Motor & Sailing Yacht

Basic Principle

MARINCO, that has always paid great attention to satisfy the requirements of its customers, ensures top quality products, as it directly manufactures almost all the components of desalinators, using the best materials on the market and employs skilled technical staff.

Furthermore, the long experience acquired thanks to the many plants installed all over the world allow at MARINCO to have a widespread customer service.

Thanks to an extended home and foreign service network, skilled Technical staff and fast intervention, MARINCO ensures a high reliability of its plants. Besides this MARINCO has an on-line service, through the Internet, so guaranteeing 24-hours-a-day prompt answer to answer any assistance problem. Furthermore, thanks to central and programmed maintenance, carried out by skilled technicians, all desalination plants can work uninterruptedly.

SELECTING THE MOST SUITABLE MODEL FOR ANY TYPE OF BOAT

When selecting the most suitable model it is very important to know the following data:

- Daily quantity of water required on board. (Should the client not know this data, it is necessary to know how many people are usually accomodated onboard.

Practical experience confirmed that consumption is around 15-25 liters a day for sailing boats and 30-40 liters a day for motor-yachts; therefore you must multiply these data by the number of people onboard and will find out the daily consumption). - Number of working hours a day of the generator (in the case that desalinator works with 220 Volts) power or the number of working hours a day of the diesel engine ( if the desalinator has a pump matching diesel engine).

The effective capacity required in liters/hour produced by the desalinator will be found by dividing, the liters/day by the hours/day.

Then, choose the suitable model by using the technical desalinator’s table, bearing in mind that nominal capacity is made with new membranes, only NaCI salt, no organic matter, with temperature not lower than 25 °C (75 °F) and no other factors. The effective capacity of a reverse osmosis desalinator of any kind and trademark is normally 20%-50% lower than the published nominal capacity.

Reverse osmosis for water treatment

AQUASTAR SERIES

from 30 l/h up to 400 l/h

REMOTE CONTROL

Simple desalinator, easy to use, ideal for sports cruisers.

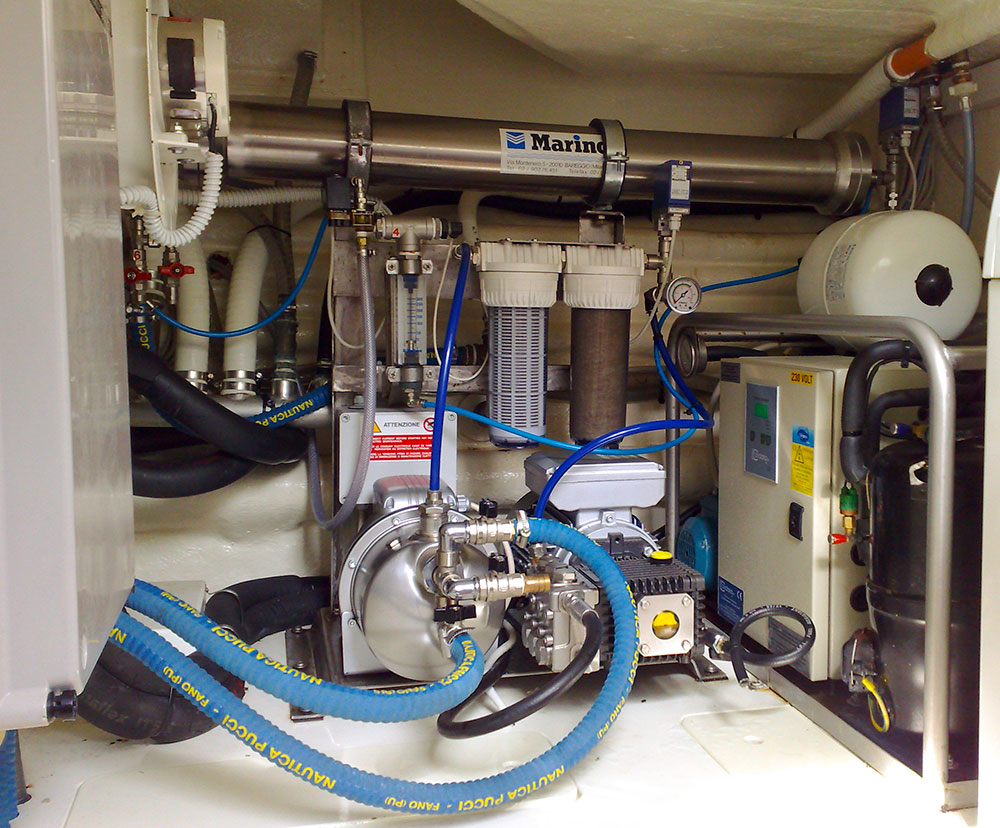

It is made of solid AISI 316 L stainless steel and is extremely enduring , thanks to its dimensions it is suitable for small spaces.

Aquastar is a machine belonging to the new generation that, in the “Plus” version, is fitted with a self-diagnosis system, transmitting data to a control panel.

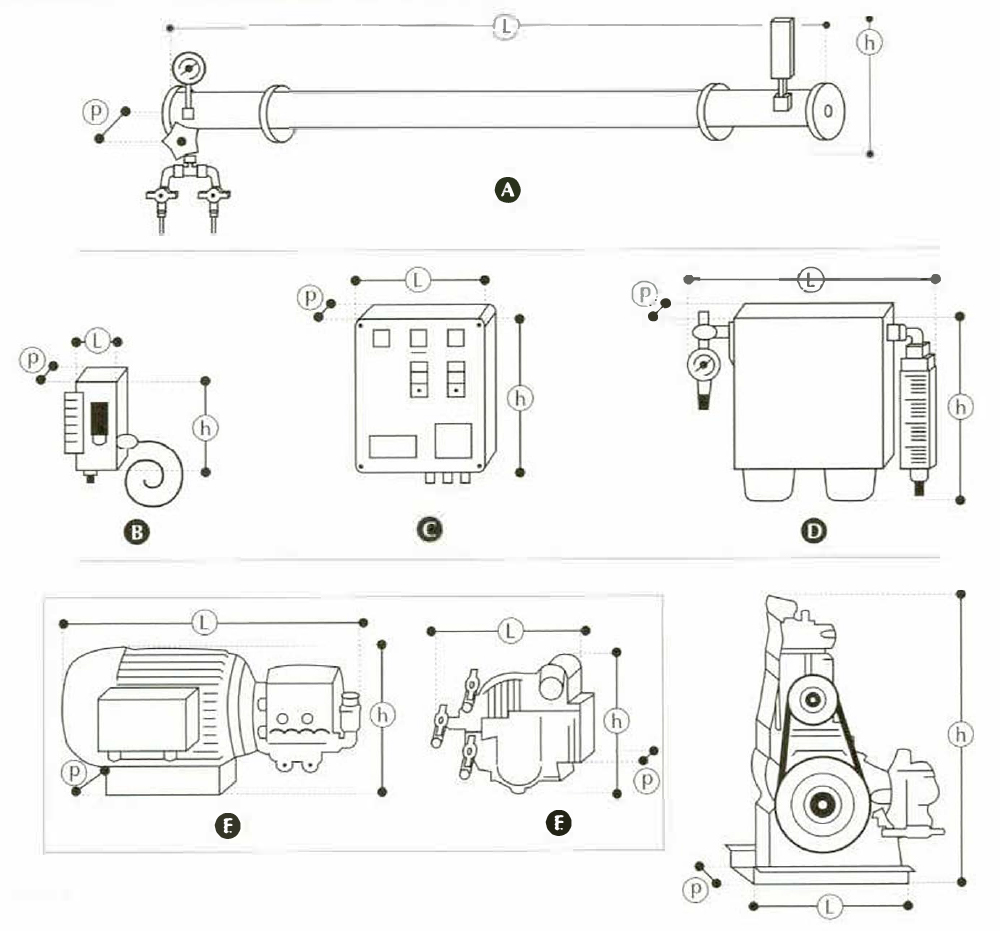

All Aquastar models can be supplied disassembled, on request.

ECOPURE SERIES

from 30 l/h up to 590 l/h

OUTSIDE APPEARANCE

Equipped with hand-operated valves for STARTING, STOPPING, WASHING and RINSING processes, they are made of AISI 316 L stainless steel and are assembled with the best components found on the market.

AQUAMARINE SERIES

from 30 l/h up to 590 l/h

TOP DESALINATOR

Born from the studies made regarding the employment of these apparatuses in the naval field. It is the smaller version of the plants operating on ships, all over the world, it works thanks to a microprocessor that makes it completely automatic and autonomous in the functioning phase and for every aspect concerning maintenance.

It can be operated also with the onboard PC or by means of a remote control. Industrial pumps and engines are “tropicalized” and adjusted to work 24 hours a day in small rooms such as the engine room of a motor yacht.